3D Printing with the Creality Ender-3 V2

Introduction

I received an early Christmas present of a 3D printer, namely a Creality Ender-3 V2. This is a fairly inexpensive open-frame 3D printer. 3D printing is oriented to the DIY crowd, so don’t expect the same ease of assembly and running as you might expect from other consumer electronics products. That being said, I did get it all up and running without any major setbacks.

One thing to keep in mind is that 3D printing is still a long way behind the replicators on Star Trek. When you ask the 3D printer to produce something, it isn’t instantaneous, and in fact they are quite slow, typically taking over four hours to print something. Further, most inexpensive printers print using melted plastic, so when Picard orders “Tea, Earl Grey, Hot”. he may get a plastic lump in the shape of a cup and saucer after waiting five hours, but no tea and no bone china.

Assembly

The assembly isn’t hard, the problem is the terrible user manual. The user manual is only an assembly guide. The pictures aren’t too bad, but some are quite cryptic, and there is a notable lack of text. I guess most DIYers will take it as a challenge. There are lots of YouTube videos on unboxing and assembly of this printer, but it takes quite a bit of scanning to find someone with the same problem I was having. I think a guide to where the cables need to run would have been most helpful. It didn’t mention how to install the tube that guides the filament into its feed nozzle. As a result this came apart the first time I printed and then was quite fiddly to get correct.

Adjustments

The main adjustment is to level the printing bed at the correct distance from the print nozzle when it’s in the home position. The nozzle has to be close enough that the plastic is still melted when it hits the bed, so that it bonds to the bed, i.e. sticks. If it doesn’t stick then it will usually catch on the print nozzle and get dragged around by the print nozzle, wrecking the print. You have to follow the manual quite precisely to get this to work. Even with this it didn’t stick well to the bed. The advice I got from a friend was to cover the bed in painter or masking tape. After covering the bed with painter’s tape and adjusting the bed leveling/nozzle height then everything worked fine.

There are lots of other adjustments, such as the tension on the guide wheels and some temperature settings. I left all these at the default. In the settings on the controller, there are quite a few options that are not documented anywhere.

Operation

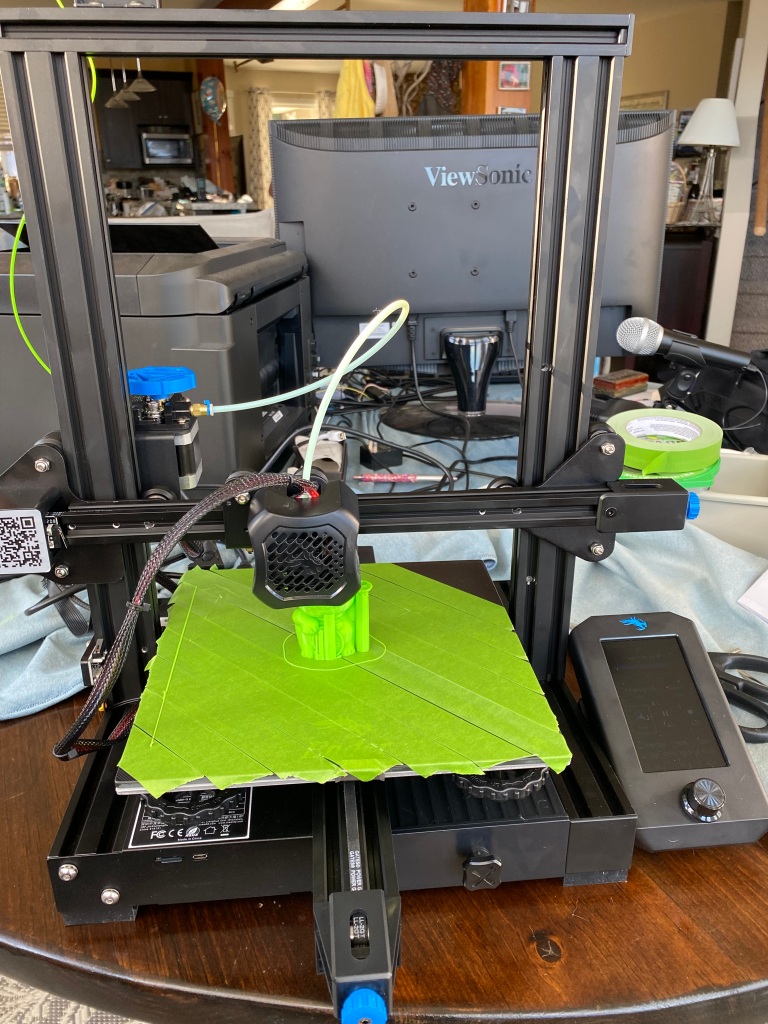

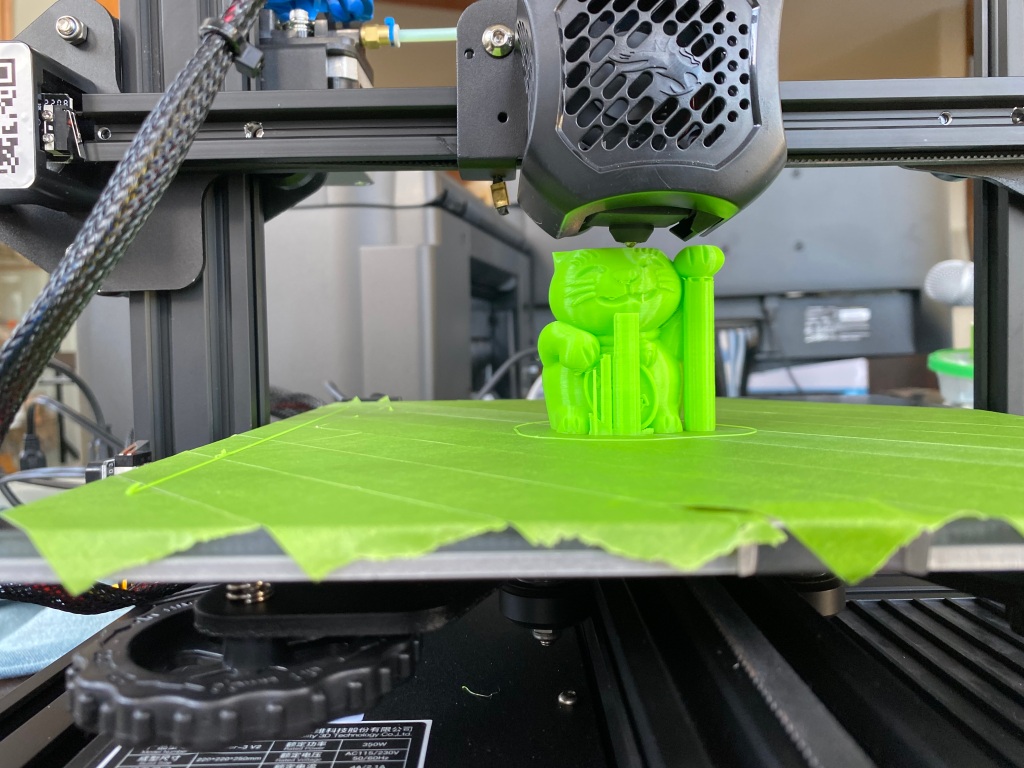

The pictures below are printing the cat sample that came on the printer’s memory card. Printing this little guy took four hours, but the result was good. The printer can’t print overhangs, each layer needs to be supported, so you can see some support structures being printed as well to support the printing of the head and the hands. These supports are easy to remove when printing has finished.

Software

The printer comes with something called “Creality Slicer” which will take a standard 3D model produced with a 3D drawing program like Blender and “slice” the model to produce a file that the printer can print. The Creality Slicer is based on the Cura Slicer and seems to work fairly well. There are lots of other slicer programs out there, but so far I haven’t had a chance to check any of them out. The memory card that comes with the printer contains a number of 3D models, that you can slice and then print.

Beside the models that come bundled with the printer, there are tons of places online where you can download all sorts of models that people have created. Thingiverse being one of the main ones.

Of course if you want to design your own objects to print then you need to learn and use 3D modeling software like Blender, which are quite complex.

Summary

The hobby of 3D printing requires a lot of patience. Patience with setting up and adjusting the printer. Patience waiting for the model to print. Patience working with 3D modeling software. That being said, there is something compelling about being able to create something in a drawing or CAD program and then actually print a physical version. The Creality printer seems good for the price, it feels solid and once going seems to be able to print without any attention. The main thing I would like to see is a proper user manual.

That’s a fantastic xmas present, but I hope you’re aware that you’ve just stepped into a very deep rabbit hole. I also started with a Creality before moving to a much faster, more accurate, more reliable, and more sophisticated CoreXY printer. The acceleration lets me print that exact same cat in about 1h20m. But getting there required some deep digging into a seemingly infinite hole haha. Enjoy, and welcome to the club!

Rabbit Hole Lex

November 28, 2022 at 6:31 pm

[…] blogged my initial impressions of my new Creality 3D printer last time. This time we’ll look at some […]

What I Learned About 3D Printing Last Week | Stephen Smith's Blog

December 2, 2022 at 10:41 am

[…] cost manufacturing tools like 3D printers and laser […]

Looking Back and Looking Ahead | Stephen Smith's Blog

January 6, 2023 at 1:44 pm